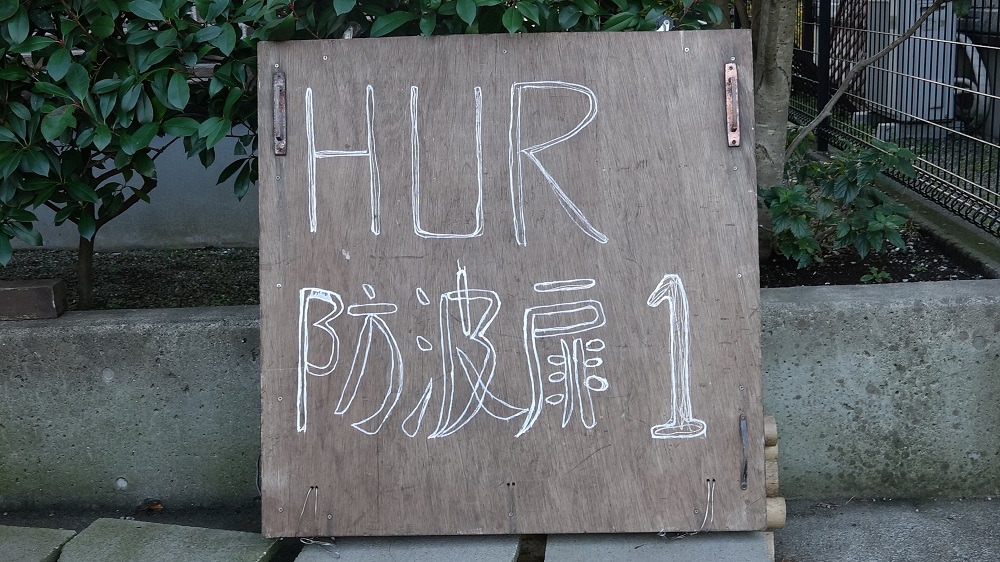

Anti-Tsunami Door 1/20 Scale model(Exhibited at WCDRR)

On March 11, 2011, eastern Japan suffered a major earthquake that was accompanied by a catastrophic tsunami, which caused everyone in Japan to realize the frailty of humanity in the face of such catastrophic natural disasters. We, therefore, decided to develop a system that could prevent or mitigate, if even by only a little, the damage caused by such huge tsunamis in order to help preserve human life and society when the next such tsunami hits.

ATL determined that the following 3 requirements were essential in an anti-tsunami system if it were to be practical:

- 1) If the anti-tsunami system were operated manually or by machinery (such as closing an opening in a breakwater), it could fail to function properly owing to a loss of power or to the inability of people to deploy the system because of the danger involved, and it was therefore realized that the system should function automatically without requiring powered machinery or personal action.

- 2) In order to prevent the system from creating an eyesore and obstructing the view, such as a massive concrete seawall more than 10 m in height, or interfering with daily life, the system should be compact and unobtrusive when not needed, but be able to be deployed and act as a breakwater when needed, such as by moving or expanding when a tsunami approaches.

- 3) Because of the great height of tsunamis possible that the system would have to be able to handle, the materials of the system should be inexpensive and the construction, simple.

After extensive research, ATL found that the buoyancy, strength and cost of lumber was perfectly suited to constructing such an anti-tsunami system that could satisfy these 3 requirements, and thus, the Anti-Tsunami Door system was invented. In the ATD system, reinforced wooden plank units (each, 2~3 m high, 5 m wide, and 20~30 cm thick) are used for the main structure, which is installed lying down on the ground near the seacoast. One side of each unit is hinged to the ground, and the opposite side is free, so that the unit will stand up in the flood water after the tsunami arrives. The erect unit is supported to resist the force of the tsunami, and the ATD then functions as a breakwater. Since the units are made of wood, the main structure is inexpensive and environmentally friendly. This system relies on the buoyancy of wood for its automatic erection to function as a breakwater, without requiring any machinery, power or human action. Because the ATD is constructed in independent units, the ATD can be used to protect a long coastline by the installation of many such units in line along the coast. Further, because an ATD unit can be constructed of multiple panels, like a folding screen, it can rest on the ground in a folded, compact configuration until a tall breakwater is needed during a major tsunami. For example, an ATD unit comprising 5 panels, each 3 m in height, would unfold to form a 15 m high breakwater, and since the thickness of one panel is just 20~30 cm, the total height of the 5 panels in a folded configuration on the ground would only be 1~1.5 m.

However, there are 2 technical issues:

- 1. Since it is constructed in units and is not watertight, can the ATD effectively mitigate the effects of a tsunami?

- 2. Since it is made of wood, can the structure and connecting parts of the ATD withstand the full force of a large tsunami? Specifically, is a wooden structure only 20-30 cm in thickness sufficiently robust to withstand the power of a large tsunami?

Regarding the first issue, in its scale-model tests, ATL found that the ATD could achieve a tsunami height reduction of 80~90% of that of a solid seawall of the same height. Because it was considered that a 10~20% reduction in mitigating effect was acceptable, ATL judged that the ATD could function as an effective breakwater. Regarding the second issue, ATL has applied reinforced wooden panels for the ATD. This is done by sandwiching a rectangular wooden frame between two wooden boards, so that the wooden materials support each other internally and improve the overall strength of the panel. These reinforced wooden panels are a far better structure for a breakwater than we expected. Since they are hollow, they can fill with flood water, and their total mass during a tsunami is thus greater and the overall structure is more robust. Moreover, the total buoyancy of the structure is not affected by this because the wooden parts have a certain, natural buoyancy and the water inside the panels and that outside the panels have the same specific gravity. Additionally, the strength required of the unit in the water when acting as a breakwater (i.e., when the unit has the same water pressure on the tsunami impact side as on the opposite side) is only for stopping water movement (i.e., there is no difference in water height on the two sides and, so, no pressure difference). So, if the unit is supported with the strength required for water movement, the unit can be kept in the required position and function as a breakwater to reduce the force of flooding. This is important because the flotsam carried along by flooding can severely damage structures, including bridge piers in rivers. The scale-model tests confirmed that the structure was not damaged under the test conditions when functioning as a seawall, even when submerged in the water. Further, the hinged connections between the ATD and ground, which were double rings of wire, were also not damaged under the test conditions. However, the supports of the ATD (used to keep ATD in the erect seawall configuration) needed to be sufficiently robust to keep the ATD in a standing position and location against the full force of the wave, even when submerged in the water. In the early testing, the supports were not strong enough and sometimes bent, and the weight of the anchors was not sufficient to resist the force of the wave, and the anchors significantly displaced. It is therefore required that the strength of the supports and the weights of the anchors used in the full-scale facilities be designed to be sufficient.